What is the difference between a globe valve and a gate valve?

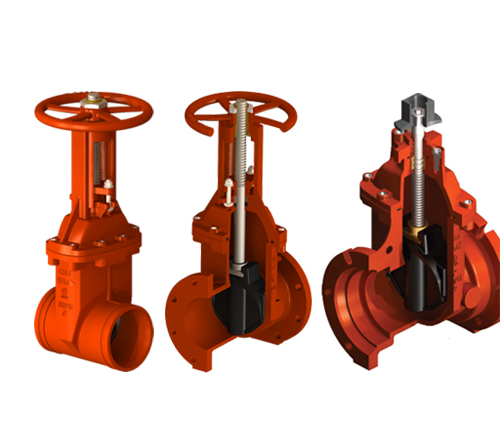

The gate valve has the same effect in both directions. There is no requirement for the direction of the inlet and outlet, and the medium can flow in both directions. The shut-off valve needs to be installed in strict accordance with the direction indicated by the arrow on the valve body. There is also a clear stipulation on the direction of the inlet and outlet of the shut-off valve.

The shut-off valve is low-in and high-out. From the outside, it is obvious that the pipeline is not on a phase horizontal line. The gate valve runner is on a horizontal line. The gate valve has a larger stroke than the stop valve.

From the point of view of flow resistance, when the valve is fully opened, the flow resistance of the gate valve is small, and the flow resistance of the load valve is large. The flow resistance coefficient of the ordinary gate valve is about 0.08 ~ 0.12, the opening and closing force is small, and the medium can flow in two directions. The flow resistance of the ordinary globe valve is 3-5 times that of the gate valve (public number: pump housekeeper). It must be closed forcibly during opening and closing to achieve the seal. The valve core of the shut-off valve only contacts the sealing surface when it is completely closed, so the wear of the sealing surface is very small. Due to the large flow force, the shut-off valve that requires an actuator should pay attention to the torque control mechanism. Adjustment.

There are two ways for the shut-off valve during installation. One is that the medium can enter from under the valve core. The advantage is that when the valve is closed, the packing is not under pressure, which can extend the service life of the packing, and can bear pressure in the pipeline in front of the valve. Under the circumstances, the replacement of packing is performed; the disadvantage is that the driving torque of the valve is large, which is about 1 times of the upper flow, the axial force on the valve stem is large, and the valve stem is easy to bend.

Therefore, this method is generally only applicable to small-diameter globe valves (below DN50), and globe valves above DN200 use the method of medium flowing from above. (The electric shut-off valve generally uses the medium to enter from above.) The disadvantage of the medium to enter from above is exactly the opposite of the way to enter below.

As a company that can truly provide you with total solutions for fire protection and safety systems, we often help customers provide installation services for fire protection systems for new or retrofit projects.

Address: 58 Huanghe South Street, Huanggu District, Shenyang City Mobile: 18624031197 (Manager Gao) Telephone: +86 24 3191 8231

Email: sales@taidi-china.com

Home | About | Product | Service | News | Contact

Copyright Shenyang Taidi Electromechanical Equipment Co., Lt Liao ICP No.15003691 Copyright ©2019 All Rights Reserved.